Dedication to Haute Horlogerie

Franck Muller OLTREMARE is proud to present its craftsmanship campaign that showcases the crafts required to create a timepiece. Thanks to its incredible in-house capabilities, the brand can push barriers of watchmaking even further with innovative complications and great technique whilst fully respecting Swiss watchmaking tradition.

Engraving

We use engraving to personalise and embellish our open-back watches. Delicate motifs, engraved on the different parts of the movements, are beautiful ornaments that give a watch its unique personality.

Côtes de Genève

This finish, known as Geneva stripes in English, looks like small parallel waves formed on a metal surface. They are present on the bridges and the rotor plate. Famous today, this form of decoration was, for many years, a distinguishing feature of watchmaking in Geneva.

Spotting

Known also as perlage in French, this decoration is made up of slightly overlapping circles or spots. It is mainly found on the bearing surfaces of the plates of watch movements. It is carried out by hand by skilled craftsmen.

Sunray brushing & Snailing

Sunray brushing is a decoration made up of straight lines running from the centre to the edge of the piece and depicts the sun’s rays. A variant of this is snailing, a pattern consisting not of straight lines but of slight spirals. These finishes can be found primarily on the rotor segment and the barrel.

Bevelling

This hand-crafted finish consists of cutting the edge between the surface and the sides of a piece, creating, most frequently, a 45° chamfer, which is then carefully polished. In addition to the aesthetic aspect, this eliminates sharp edges, a source of crenellation, which could interfere with the proper functioning of the movement.

Mirror Polishing

Mirror polishing, also known as black polishing or block polishing, represents the highest possible degree of polish. It leaves no visible traces and produces outstanding optical effects. Light is reflected in only one direction and, depending on the orientation, the piece changes from deep black to bright white.

Shot-blasting

Shot-blasting is a surface treatment process, similar to sanding. It involves subjecting a surface to a stream of glass microbeads, which strips it without damaging it. The surface thus obtained is shiny, like satin. In addition to the aesthetic aspect, it also eliminates sharp edges, which are a source of crenellation.

Satin-finishing

This involves decorating a metal surface with a series of extremely fine, parallel stripes. The effect created is regular, clean and catches the light from several angles. It must be uniform and, above all, the alignment of the micro-stripes must be flawlessly parallel.

Circular Graining

The Circular Graining is a circular satin finish, a form of smoothing that produces fine circular lines and adds shine. This decoration is achieved by pressing a “baff”, a buffing stick, onto the surface of a rotating piece.

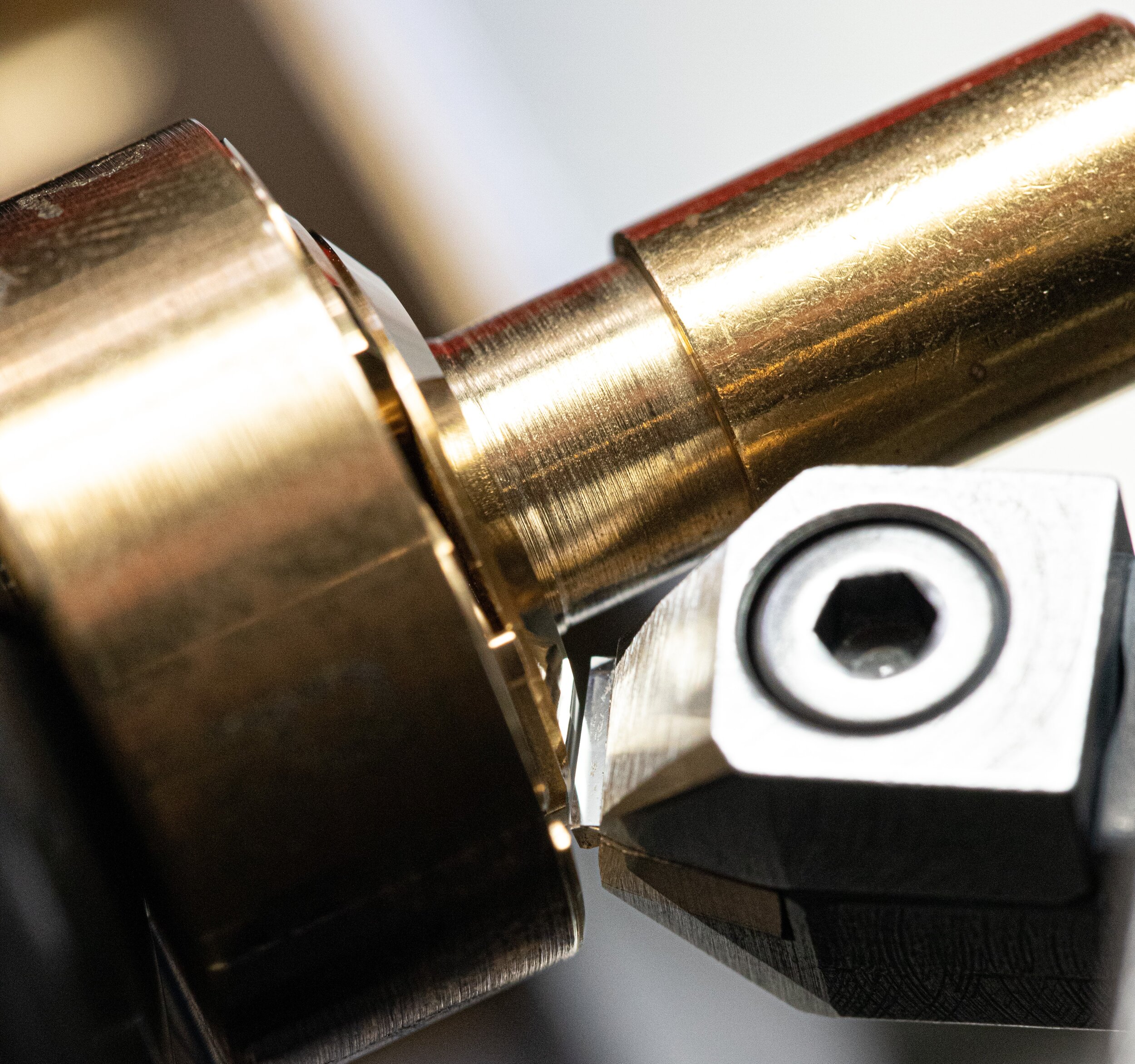

Diamond polishing

Diamond polishing is carried out by turning or milling on non-ferrous metals, using tools set with diamonds. Diamond polishing is used to produce high gloss surfaces, such as on bridge bevels.

Drawing

The craftsman first removes machining marks and burrs from the flanks, then begins the étirage or drawing process, using different files to achieve a smooth, clean appearance. These processes leave marks and striations. Careful smoothing and polishing will result in a honed, even surface, which is essential for good bevelling.

Rhodium plating

Rhodium plating consists of electrolytically depositing a layer of 24k gold and then rhodium on a component to prevent corrosion and extend its life.